INTRODUCTION:

In today’s rapidly evolving business landscape, environmental consciousness and sustainability is gaining paramount importance. Environmental Sustainability is not just a buzzword today, but is of imperative importance to all the businesses operating either at national or international level. Companies are increasingly inclined towards integrating Environmental Social and Governance (ESG) strategies into their processes or operations. One of the major parts of any business is the “Supply Chain” and “End Product Logistics” , the sustainability of which is of paramount importance for any organization to become sustainable. The integration of ESG factors into the upstream and downstream activities of the supply chain is getting more critical with every passing year. By adopting the holistic approach of ESG integration, companies can not only mitigate the future risks but can also uncover the innovation, cost saving and competitive advantages.

GREEN SUPPLY CHAIN

Green Supply Chain covers the entire lifecycle of the product, from raw materials sourcing to product delivery to end of the product lifecycle and the method of its disposal. At its core, the green supply chain is developed with the aim to reduce environmental impacts, conserving natural resources, and promoting sustainability at every stage of the supply chain. From procurement of sustainable raw material, natural resource consumption during manufacturing of the product, method of transportation or distribution, disposal after life over, each step is carefully optimized to minimize carbon emissions, waste generation and ecological footprint.

Key elements of a Green Supply Chain:

- Sustainable Sourcing: Procuring raw materials from suppliers or vendors that are having sustainable manufacturing processes, complying with environmental norms, opting for eco-friendly practices such as organic farming, renewable energy, tree plantation, rainwater harvesting, etc.

- Energy Efficiency: Implementing energy efficient technologies during product manufacturing, transportation and logistics warehousing so as to reduce greenhouse gas emissions and optimized energy consumption.

- Waste Reduction & Recycling: Minimizing the waste generation by the process of circular economy initiatives , recycling programs so as to reduce the generation of waste. This will promote reuse of the products and components and hence will conserve overexploitation of natural resources. Optimizing the packaging size and shape will also help in reducing the plastic packaging waste.

- Logistics Optimization: Streamlining the transportation routes, consolidating shipments, alternative transportation methods (like sea or rail routes) instead of airlifting, relying more on locally sourced products, switching over to common warehouses or Milk-run concepts to minimize the distance of transportation and hence reduce GHG emissions.

- Product Sustainability: Manufacturing the products with longevity, recyclability and environmental impact in mind using eco-friendly materials and packaging.

ESG INTEGRATION IN GREEN SUPPLY CHAIN:

Environmental Sustainability – From Green Procurement to Circular Economy:

Environmental Consciousness and sustainability is the key pillar of ESG on which “Green Supply Chain” is based. Companies are increasingly working towards green procurement practices such as sourcing and purchasing the components or products from suppliers that are involved in environmental stewardship. This include assessing the vendor’s ecological footprint like carbon and water footprint, energy efficiency, water usage and waste management.

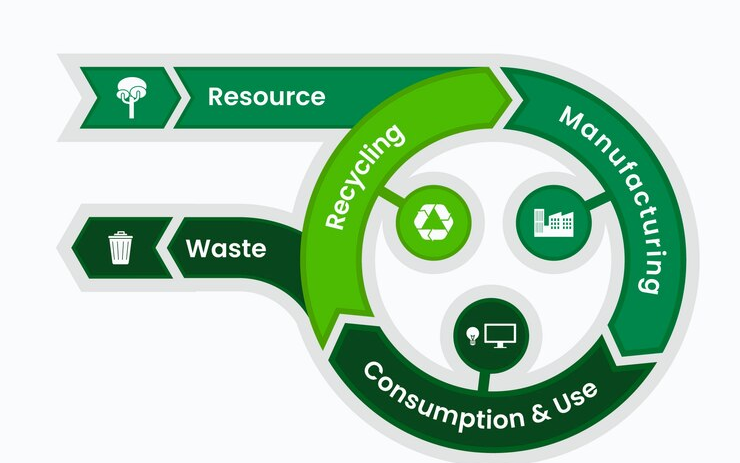

Moreover, there is growing emphasis on circular economy i.e. the after life cycle of the product. In this the products are designed to be reused, remanufactured or recycled. By increasing the life cycle of the product, companies can reduce their waste generation and can optimize the consumption of natural resources which in turn minimizes the environmental impact of the product manufacturing.

Social Responsibility – Ensuring ethical Labor Practices And Human Rights:

The Social Responsibility Pillar is another significant pillar for integrating Environmental Social and Governance in the Sustainable Supply Chain. Companies are under increasing pressure to check on the labor laws and practices followed by their vendors across the entire supply chain. This means conducting thorough due diligence on suppliers’ labor conditions, the way they are implementing Diversity, Inclusion and Equity in their overall manufacturing process, worker’s condition and fair compensation practices, adherence to international laws, etc.

By fostering transparency and ethics in the supply chain, companies can build trust among their vendors. This helps businesses to mitigate the risk of reputational damage, legal liabilities while safeguarding the wellbeing of the workers and communities, building goodwill among investors, etc. Collaborative efforts like Vendor Training programs and audits play a vital role in promoting social responsibility.

Governance and Compliances – Upholding Ethical Standards and Regulatory Requirements:

Governance Pillar is another significant pillar that is required to be integrated in the Green Supply Chain. Companies must uphold the highest standards of corporate governance, integrity, and ethos across the entire supply chain network. This includes having robust policies for anti-corruption and bribery, fair competition for all stakeholders, adhering to registry requirements, etc.

Furthermore, businesses are increasingly leveraging technologies such as Block Chains and Digital Platforms to enhance Supply Chain Transparency. These technologies provide real time information regarding the supplier’s compliance performance and facilitate rapid response to all the Environmental Social and Governance related risks and opportunities.

CASE STUDIES AND BEST PRACTICES:

IKEA: The Swedish Furniture company sourced 98% of the wood used in its products from FSC certified sources or from recycled sources in 2020 and has sustained the same till FY23. IKEA produced 44% of its plastic products from recycled or renewable materials in 2020. It has also committed to achieve 100% renewable energy usage by 2030.

PATAGONIA: The International clothing brand is famous for its commitment towards sustainability and implementing fair labor practices across its entire supply chain. Through their “Supply Chain Environmental Sustainability Program”, Patagonia measures suppliers’ sustainability initiatives against their own environmental standards. The purpose of this program is to measure and reduce the environmental impacts of manufacturing Patagonia products.

TOYOTA: The automobile manufacturer pioneered the concept of “Lean Manufacturing” which emphasizes on waste reduction and continuous improvement resulting in significant environmental and cost benefits. In 2020, Toyota launched four sustainability standards together with their suppliers:

Carbon Neutrality

Sustainable Raw materials

Workforce Well-being

Circular Value Chain

CONCLUSION:

In conclusion, integration of Environmental Social and Governance in Supply chain is not just moral or social responsibility, but is imperative for the businesses as well. By accommodating Environmental Social and Governance considerations into their supply chain, businesses can develop more resilient and responsible supply chains that drive long term value chain.

From mitigating climate risks and promoting fair labor practices, Environmental Social and Governance offers a roadmap for organizations to build sustainable businesses and to navigate through the complexities of the interconnected world. Integrating the same sustainability standards across their supply chain, organizations can play a pivotal role in shaping a more equitable and prosperous future for generations to come.